Nothing throws a wrench in spray season like unexpected downtime. One minute, you’re ready to roll, and the next, you’re sidelined by a clogged nozzle or a worn-out pump. The good news? Maintenance can go a long way in keeping your sprayer running smoothly and your applications on point. With the right prep, you can stay ahead of breakdowns and make the most of every spray window.

When it comes to preseason maintenance, preparation should start at the end of the previous season. Take some time to reflect on how your spray season went and identify things to take care of during the off-season.

After the last use of the season, avoid the urge to clean your machine right away. Instead, let the dust and dirt that sits on the machine help detect leaks that you wouldn’t be able to see if the machine were spotless. When evaluating your sprayer during this time, pay special attention to:

-

potential kinks in the lines

-

hoses that may be rubbing on the frame

-

loose or defective clamps, fittings or nozzle bodies

Scheduling a preventive maintenance inspection with a local dealer can help identify minor issues before they become major problems, saving time and money when spraying begins.

Routine maintenance critical

When it comes to sprayers, the little things add up. A small hydraulic leak forces the pump to work harder, leading to wear and possible system failure. Likewise, an unnoticed crack in the boom can worsen under stress, causing a costly midseason breakdown.

Routine inspection and maintenance can help prevent these unexpected breakdowns and keep the sprayer running smoothly. Before each use, perform a quick check of key components:

-

Fluids and engine. Check oil, coolant and hydraulic levels. Replace worn filters and tighten belts.

-

Hoses and booms. Look for leaks, cracks or wear. Minor issues can lead to expensive repairs.

-

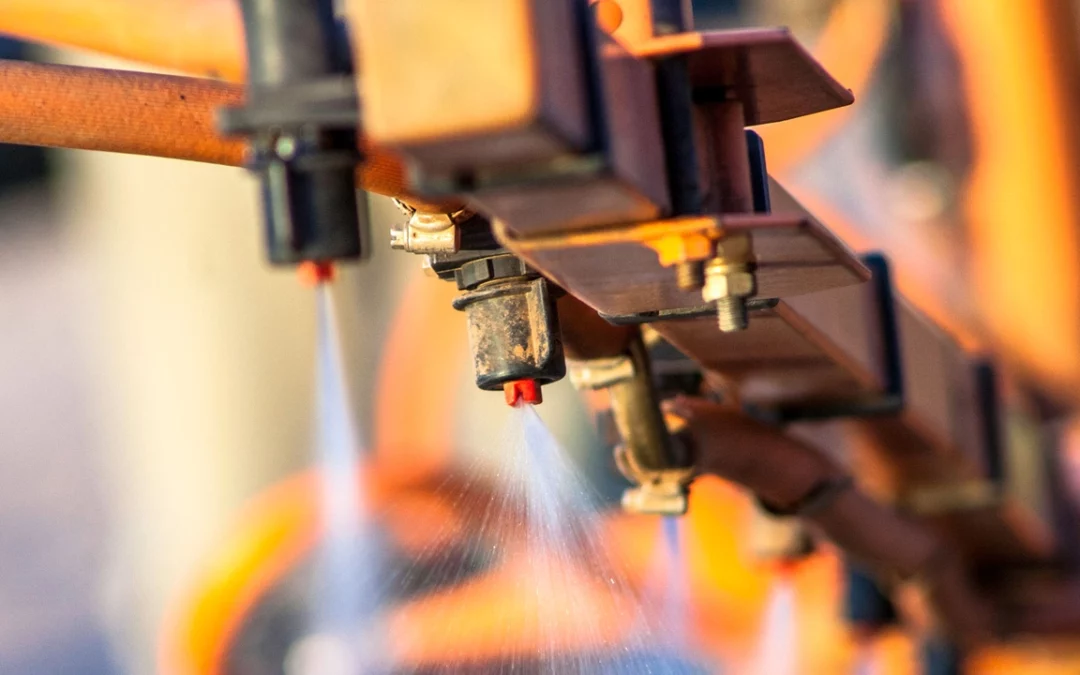

Spray system. Rinse the boom, inspect nozzles for wear and test pumps for proper pressure.

-

Tires and electrical. Maintain proper tire inflation, and check lights and wiring for safety.

Keep nozzles a priority

Worn or clogged nozzles can throw off your spray pattern, leading to uneven coverage, wasted product and reduced effectiveness. Regularly check nozzles for wear, clogs or damage to maintain application accuracy. A good rule of thumb is to replace tips after about 30,000 acres. Don’t forget to rinse the boom to ensure any leftover product makes its way back to the tank.

Choosing the right nozzles for the job is just as important. Consider factors like chemical requirements, drift control and flow rate. Not sure which nozzle fits best? Talk with your local dealer or use a spray nozzle calculator to help you dial in the right option for optimal performance and minimal drift.

Tap into available resources

You don’t have to troubleshoot sprayer issues alone. With today’s technology, plenty of resources are available to help maintain and optimize equipment. Many companies offer guides, product updates and troubleshooting videos.

Local dealerships are excellent resources when you need more personalized support. They offer expert advice, service options and tailored solutions to help you get the most out of your spraying season.